Ever wondered why in Western Australia diesel engines are so popular? Diesel engines are perfect for our WA lifestyle. They are economical and deliver high torque which is perfect for towing caravans. But how do they work?

A little knowledge in this area goes a long way, and at the heart of the Perth Diesel engines, Diesel fuel injection systems are essential for your engine’s performance, delivering precise fuel amounts to the combustion chamber. They work by compressing air to high temperatures and injecting atomised fuel directly into it, causing spontaneous ignition. Key components include the fuel pump, injectors, and electronic control unit.

There are several types, like direct injection and common rail systems, each offering unique benefits. Regular maintenance, including filter replacements and injector cleaning, is essential for peak performance. Understanding these systems can help keep your diesel vehicle running smoothly and efficiently. AME Automotive mechanics have created this blog to help you understand the complexities of diesel fuel injection, how it works, and how it can make your engine more powerful and efficient.

What is a Diesel Fuel Injection System?

A diesel fuel injection system delivers precisely measured amounts of fuel into the engine’s combustion chambers. It’s an essential component for your vehicle’s performance and efficiency. At AME Automotive, our expert mechanics in Canning Vale specialise in fuel injection services, including injector cleaning and system diagnostics. We’ll make sure your diesel engine runs smoothly, whether you’re driving a Landcruiser, Land Rover, BMW, Mercedes, or even a VW. We can help you to maintain peak fuel economy and power output. We’ve got you and your diesel vehicle covered.

Basic Principles of Diesel Fuel Injection

In a diesel engine, the compression stroke is at the heart of the fuel ignition process. As the piston moves upward, it compresses air in the cylinder, raising its temperature considerably. At the compression peak, fuel is injected directly into this hot compressed air, causing it to ignite spontaneously and drive the piston downward. Let’s look at the basic principles of diesel fuel injection below.

Compression Stroke

During the compression stroke, the piston moves upward, drastically reducing the air volume within the cylinder. This action causes the air temperature to rise markedly, often exceeding 538°C at AME Automotive, we know that intense heat is essential for igniting the fuel when it’s injected. The high compression ratio in diesel engines guarantees efficient combustion and power generation.

Fuel Injection

Fuel injection kicks off the combustion process in diesel engines. It’s a vital moment where precision meets power. As diesel enthusiasts, you’ll appreciate how the system injects fuel directly into the combustion chamber under high pressure. This process atomises the fuel into a fine mist, essential for efficient combustion. You’re witnessing the heart of your engine’s performance, where every droplet counts towards maximising power and efficiency.

Components of Diesel Fuel Injection Systems

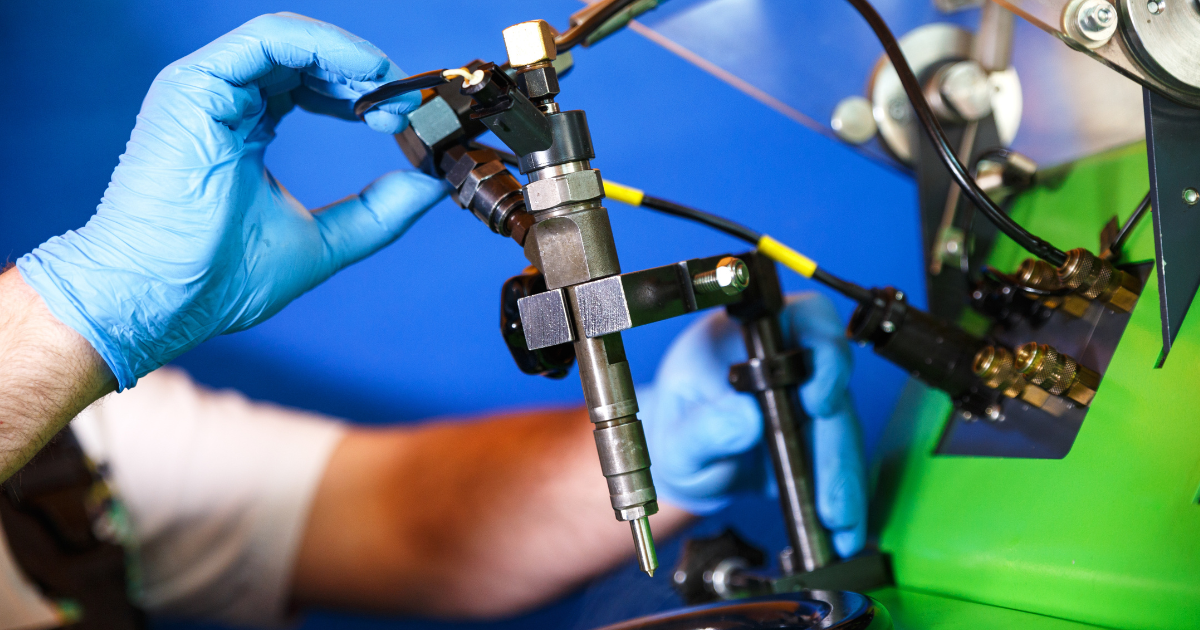

The fuel injectors, consisting of a nozzle and needle valve, precisely atomise and spray fuel into the combustion chamber. A solenoid controls the injector’s operation, while a high-pressure pump guarantees the fuel reaches the injectors at the correct pressure for ideal combustion. Below are the components of diesel fuel injection systems.

Fuel Injectors

At the heart of diesel fuel injection systems, fuel injectors play an essential role in engine performance. They’re responsible for delivering precisely measured amounts of fuel at the right moment. Operating under extreme pressures up to 36,000 PSI, these components guarantee efficient atomisation and combustion. As a Perth mechanic, AME Automotive know that adequately functioning injectors are vital for maintaining peak engine efficiency, power output, and emissions control in diesel vehicles.

Nozzle

Within the injector assembly lies another critical component: the nozzle. It atomises the fuel into a fine mist, ensuring a consistent spray pattern. This process is essential for achieving complete combustion in your diesel engine. By creating a uniform fuel distribution, the nozzle helps optimise your engine’s performance, fuel efficiency, and emissions. You’ll find this technology working hard in diesel engines across Perth.

Needle Valve

The needle valve plays an essential role in the diesel fuel injection system. It regulates fuel flow by opening and closing the injector’s nozzle. This vital component guarantees precise timing and metering of fuel delivery. The needle valve’s operation directly impacts engine performance, fuel efficiency, and emissions. Understanding its function helps us diagnose and maintain diesel engines more effectively.

Solenoid

Moving from the mechanical precision of the needle valve, another essential component in diesel fuel injection systems is the solenoid. This electromagnetic coil is critical for controlling the injector’s operation. It opens and closes the injector based on signals from the engine’s electronic control unit (ECU). Solenoid’s precision directly impacts your engine’s performance, fuel efficiency, and emissions. It’s an essential part of your diesel engine’s intricate system.

High-Pressure Pump

The high-pressure pump is an essential component for pressuring fuel to extreme levels. This critical part guarantees that fuel can overcome the intense pressures within the combustion chamber, enabling efficient injection. A well-functioning high-pressure pump is essential to maintaining your diesel engine’s performance, fuel efficiency, and emissions control. It’s an essential component that every Perth diesel owner should understand.

Fuel Lines and Filters

Following the high-pressure pump, fuel lines and filters play a vital role in the diesel fuel injection system. These components transport and clean the fuel before it reaches the injectors. They’re essential for preventing contaminants from clogging the system, ensuring your engine runs smoothly. As a Perth driver, you’ll appreciate how these parts contribute to your vehicle’s performance and longevity. Regular maintenance of fuel lines and filters is critical to peak engine function.

Types of Diesel Injection Systems

There are two primary types of diesel injection systems: Direct Injection (DI) and Indirect Injection (IDI). In DI systems, fuel is injected directly into the main combustion chamber, improving efficiency and power. On the other hand, IDI systems inject fuel into a pre-chamber or swirl chamber before it enters the main combustion chamber, which can provide smoother operation at lower speeds. The following explanation outlines the differences between these systems.

Direct Injection (DI)

Direct injection (DI) systems represent a significant advancement in diesel engine technology. In these systems, fuel is injected directly into the combustion chamber, giving you greater control over fuel delivery. You’ll experience improved engine efficiency and reduced emissions as a result. DI allows for precise timing and atomisation of fuel, optimising the combustion process. This technology has become standard in modern diesel engines, enhancing your vehicle’s performance and environmental impact.

Indirect Injection (IDI)

Indirect Injection (IDI) systems represent an earlier approach to diesel fuel delivery. In these systems, fuel is injected into a pre-chamber, where initial combustion begins. This process then spreads to the main chamber. While IDI systems were once standard, they’re less prevalent in modern engines due to their lower efficiency compared to Direct Injection (DI) systems. As a Perth diesel enthusiast, you’ll find IDI systems mainly in older vehicles.

Maintenance and Services

Regular maintenance of diesel fuel injection systems is essential for ideal engine performance and longevity. You’ll need to schedule periodic services, including fuel filter replacements, injector cleaning, and system diagnostics. At AME Automotive in Perth, we offer thorough inspections to detect issues early. We’ll check for wear, leaks, and contamination, ensuring your system operates efficiently. Don’t overlook proper fuel quality and storage to prevent system damage.

Talk to the Experts at AME Automotive

When it comes to diesel fuel injection systems, expert advice can make all the difference. Yes, that’s right! At AME Automotive, we offer a team with over 30 years of experience in automotive mechanics. We’re your local specialists in Canning Vale, Perth, offering high-quality service for all makes and models. With our family-run business, you’re guaranteed quality, honesty, and exceptional customer service. Trust AME Auto to keep your diesel engine running smoothly and efficiently or you can check out our “Pamper My Car” service deal here.

Frequently Asked Questions

How Do Extreme Temperatures Affect Diesel Fuel Injection System Performance?

Extreme temperatures can considerably impact your diesel fuel injection system’s performance. Cold weather thickens fuel, reducing flow and combustion efficiency. Hot temperatures can cause vapour lock, disrupting fuel delivery. You’ll notice reduced power and potential starting issues.

Can Biodiesel Be Used in All Types of Diesel Injection Systems?

You can use biodiesel in most modern diesel injection systems, but it’s not suitable for all. You’ll need to check your engine’s compatibility, as some older systems may require modifications. Always consult your manufacturer’s recommendations before switching fuels.

What Are Common Signs of a Failing Diesel Fuel Injector?

You’ll notice poor engine performance, rough idling, and decreased fuel efficiency. You might hear knocking sounds or see excessive exhaust smoke. Your check engine light may illuminate, and you’ll experience misfires or difficulty starting the engine.

How Often Should Diesel Fuel Injectors Be Cleaned or Replaced?

You’ll want to clean your diesel fuel injectors every 50,000 to 100,000 kilometres. However, replacements are typically needed after 250,000 kilometers. Regular maintenance keeps your engine running smoothly. Don’t forget to consult your vehicle’s manual for specific recommendations.

Are There Any Aftermarket Modifications to Improve Diesel Injection System Efficiency?

You can boost your diesel injection system’s efficiency with aftermarket modifications like high-flow injectors, upgraded fuel pumps, and performance chips. These enhance fuel atomisation and delivery, improving power and fuel economy. Always consult a professional for installation like AME Automotive.

Final Thoughts

You’ve now gained valuable insight into diesel fuel injection systems. Armed with this knowledge, you’ll better understand your vehicle’s performance and potential issues. Remember to keep up with regular maintenance and pay attention to any changes in your engine’s behaviour. If you’re unsure about anything or need expert car service assistance, don’t hesitate to reach out to the professionals at AME Automotive in Perth. We’re ready to help you keep your diesel engine running smoothly. Contact us today!